Hot Stamping Hot Stamping |

Hot stamping is a special method which includes operations

of heating, forming, cutting and quenching of sheet metal. By hot stamping

method, strong and lightweight parts are manufactured.

We take charge of manufacturing dies which hold the key of

a new method of hot stamping. |

|

|

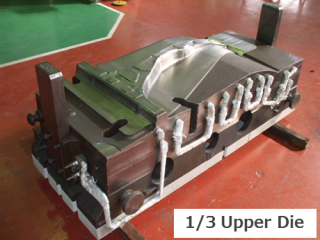

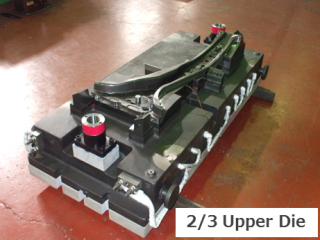

■ Dies for Forming

(1/3 Process) |

First process is forming. The dies are kept hot circulating

high-temperature oil through pipes.

Size:1,860*700*900

Mass:5,350Kg

Material: FCD550 |

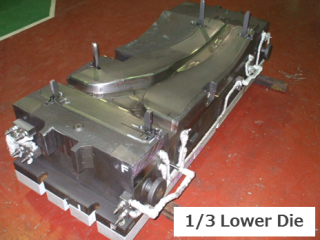

■ Dies for Cutting

(2/3 Process) |

|

|

Second process is cutting off unecessary parts. The same thermal

function as dies for forming is adopted. Edges of cutters are made by SKD

diffusion bonding.

Size: 1,860*800*900

Mass: 4,900Kg

Material: FC250+SKD |

|

|

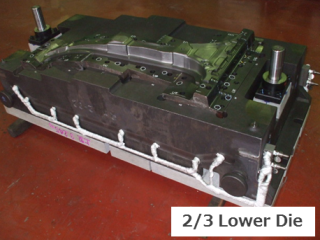

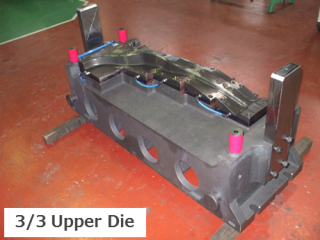

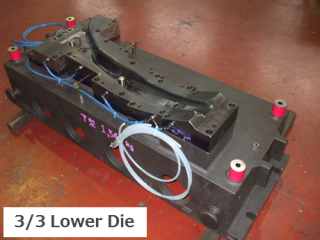

■ Dies for Quenching

(3/3 Process) |

Final process is quenching. Heated products are cooled rapidly by running water through the pipes, and hardened.

Size:1,700*600*900

Size:2,650Kg

Material:FC250+SKD |

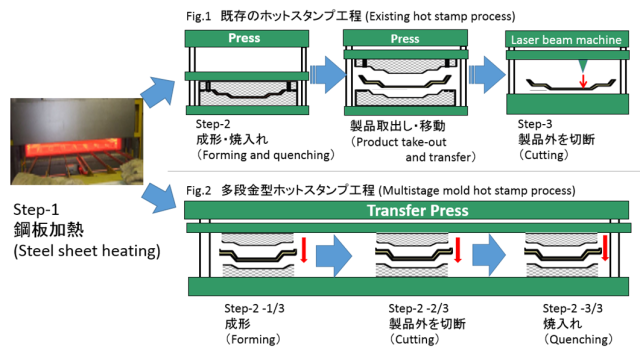

| ■Our New Method of Hot Stamping |

|

Fig.1 shows the process of conventional hot stamping method.

Step-1:Heating steel sheet

Step-2:Forming and quenching

Step-3:Cutting unnecessary parts by a laser.

The process requires laser cutting because products are hardened by quenching.

Fig.2 shows our new method of multistage mold hot stamping.

Three operations of forming, cutting and quenching can be perfomed by single

press machine.

Compared with the conventional hot stamping method, it takes shorter time for stamping. |

|

| Go back to top of this page |

|

|

| Copyright (C) 1998 Imanishi Manufacturing Co.,Ltd. All Rights Reserved. |

|